Sintered Wire Mesh Manufacturers & Suppliers

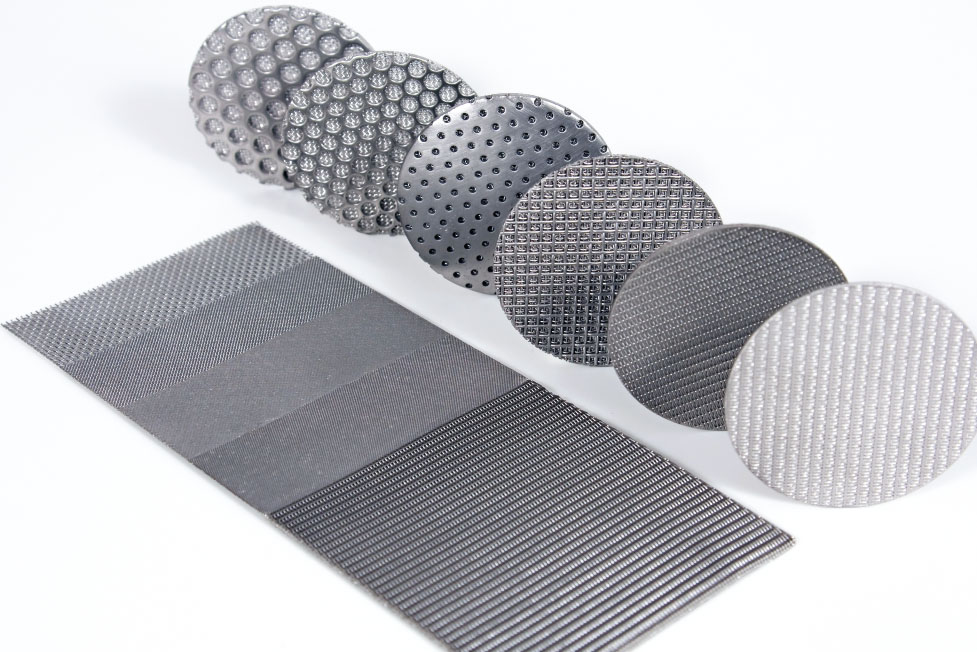

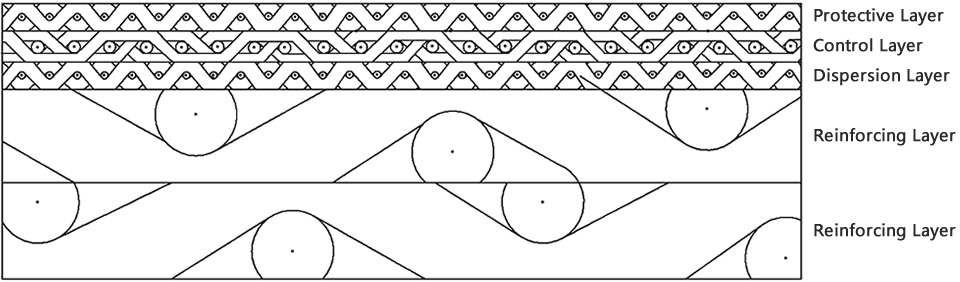

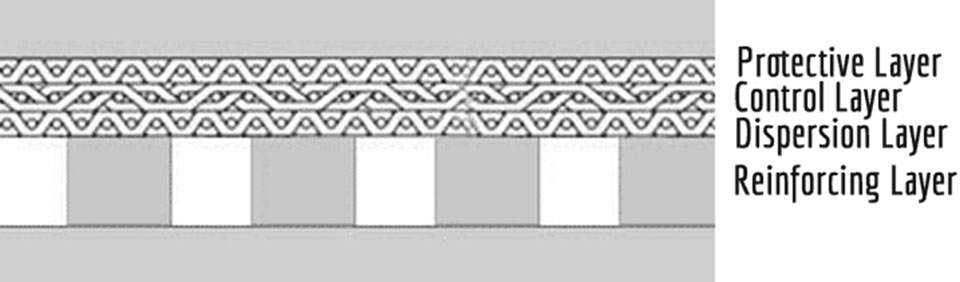

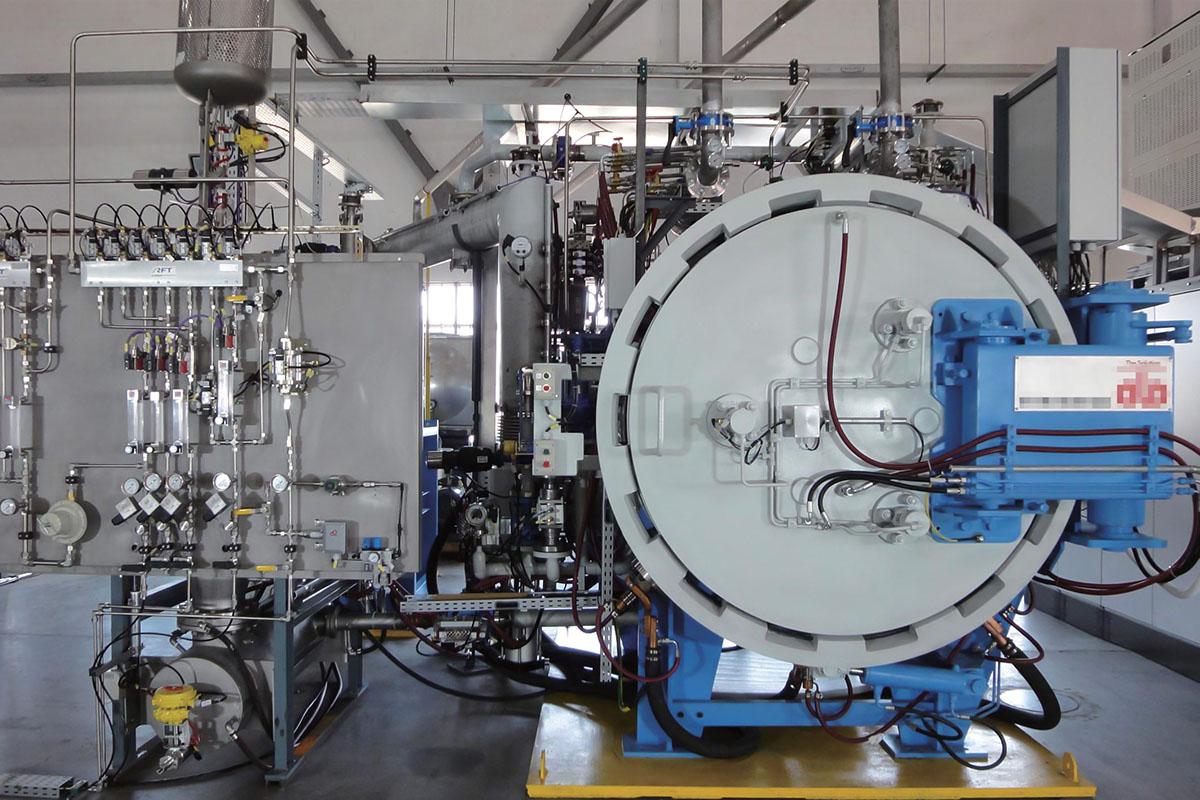

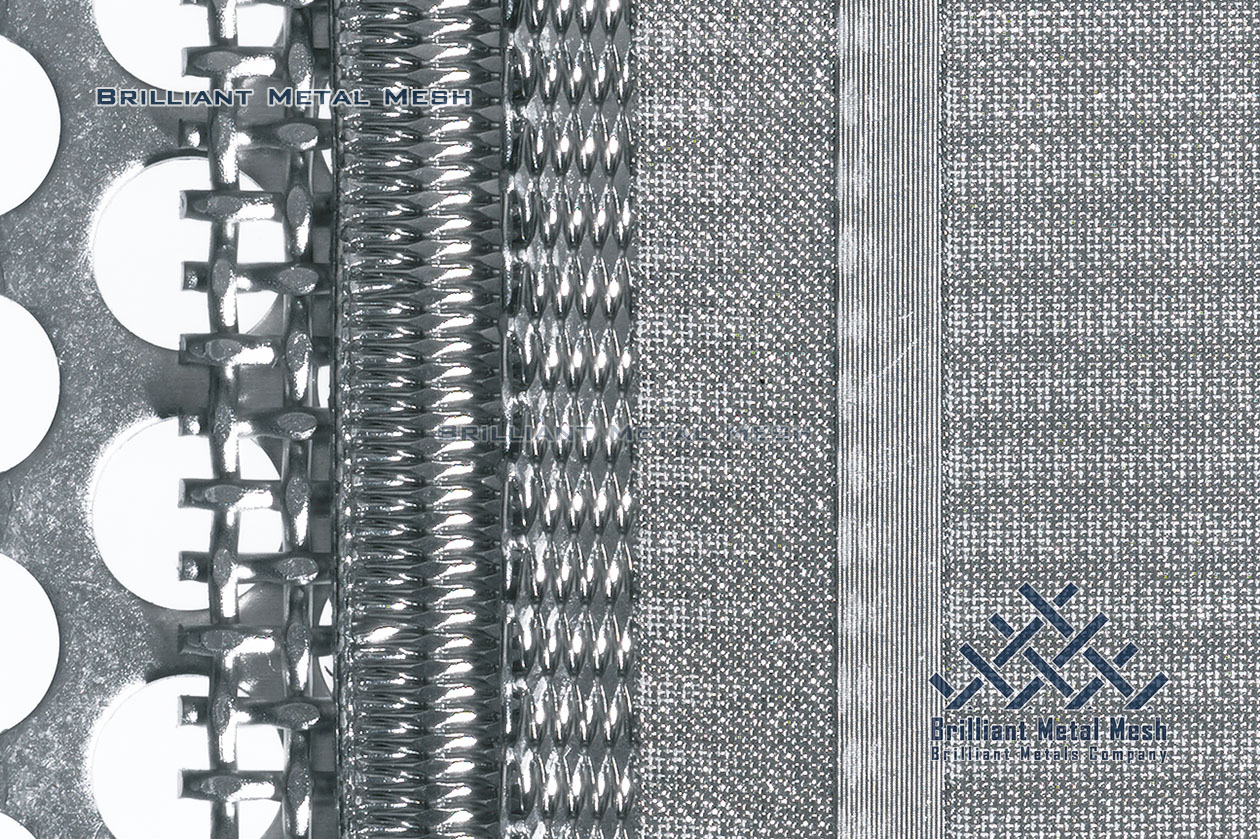

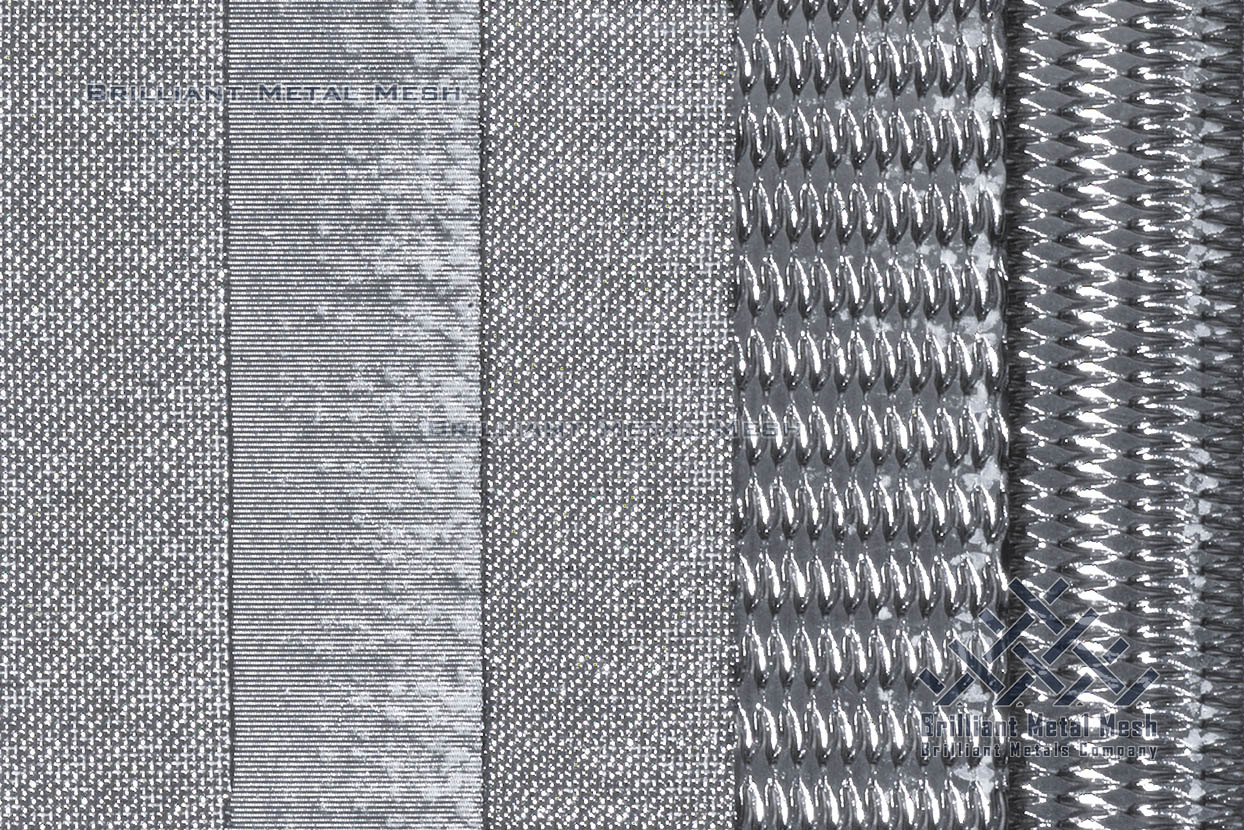

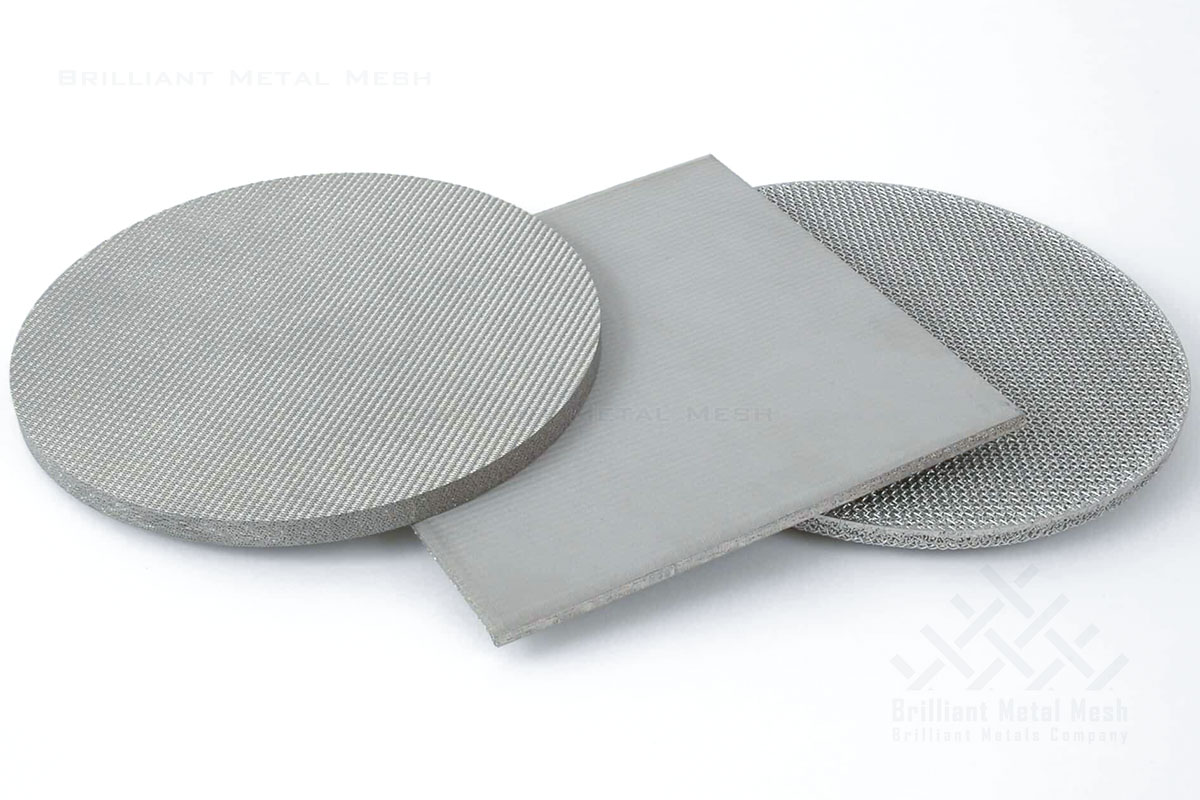

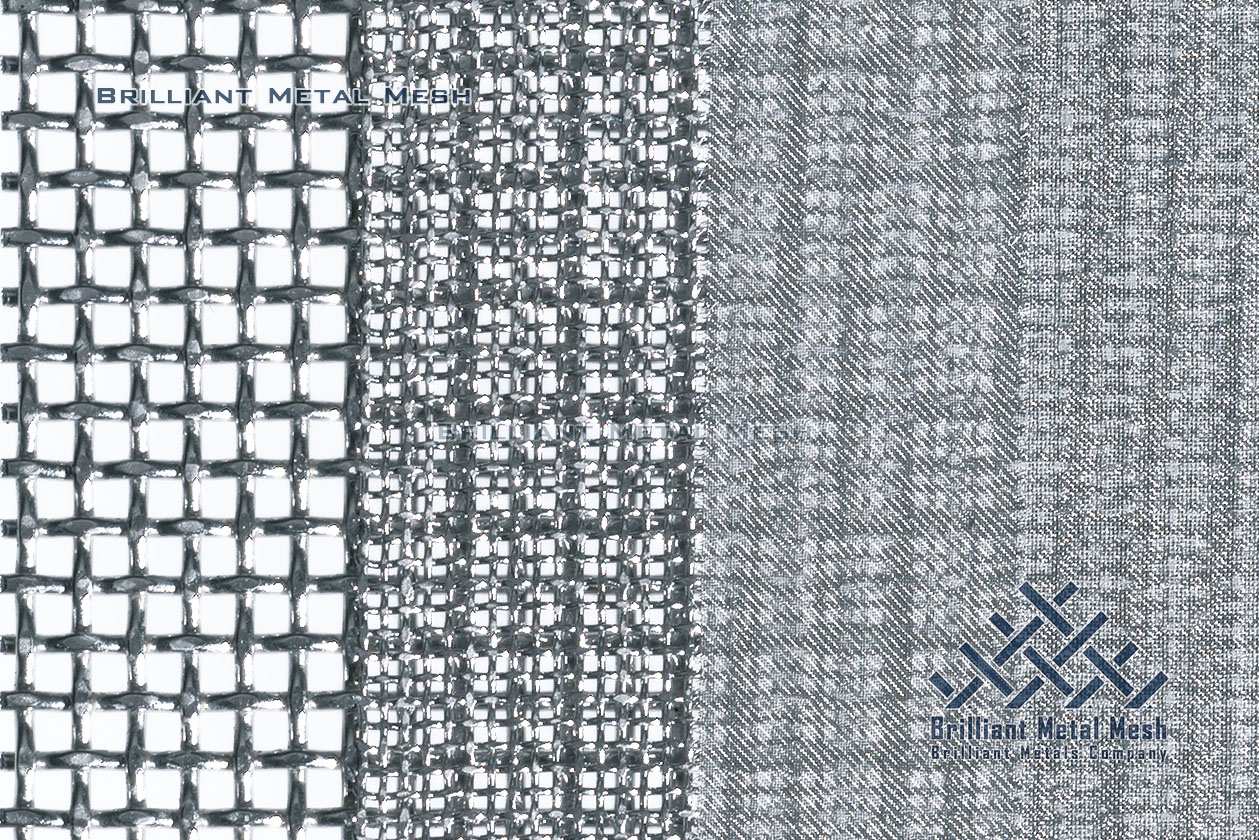

Sintered wire mesh is a type of metal filter media made from multiple layers of woven wire mesh that are fused together through a sintering process. This process involves applying heat and pressure to the woven wire mesh layers, which causes the wires to bond at their contact points, creating a strong and durable mesh structure. The sintering process also results in the formation of uniform, evenly distributed pores throughout the mesh.

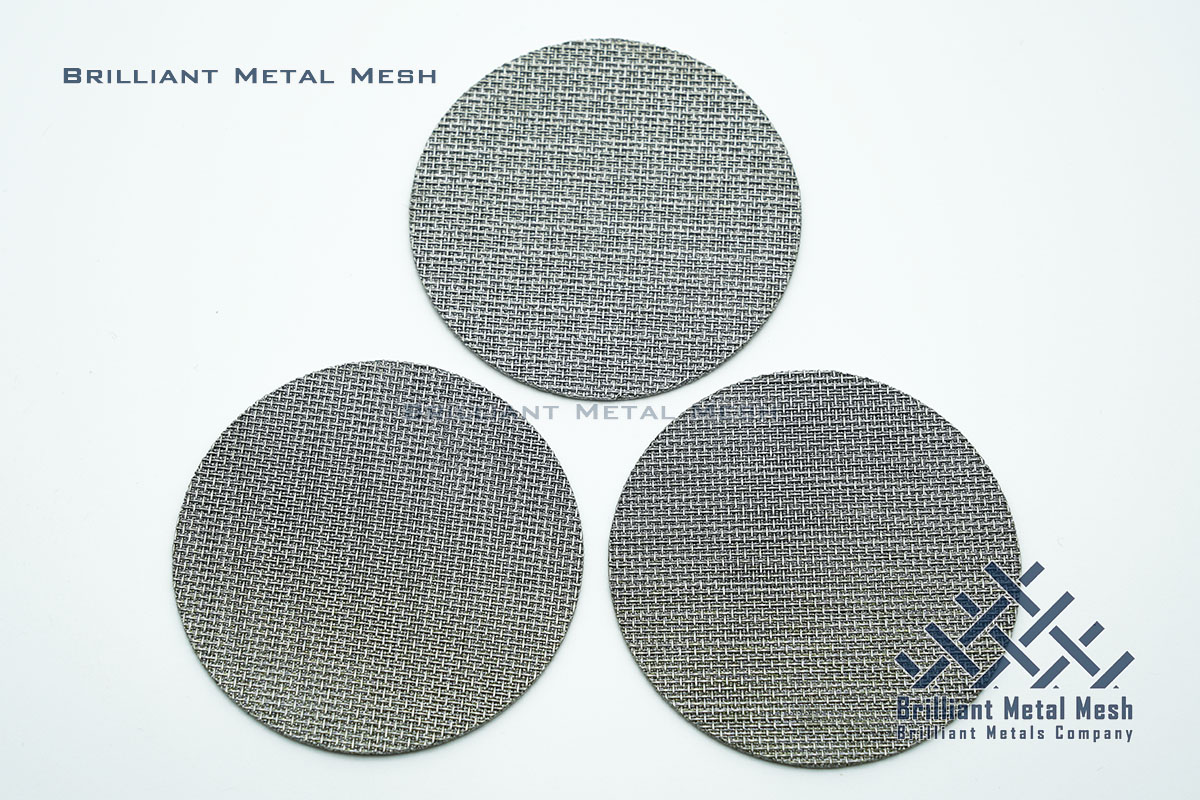

Brilliant Metals is one of leading sintered wire mesh manufacturers and suppliers in China, specializing in producing high-quality filter media for diverse industrial applications. Their sintered wire mesh is crafted using advanced manufacturing techniques, ensuring exceptional strength, corrosion resistance, and precise filtration capabilities. With a commitment to quality and innovation, Brilliant Metals delivers reliable solutions tailored to meet the stringent requirements of modern industrial filtration systems.