Stainless Steel Wire Mesh Manufacturer & Supplier in China

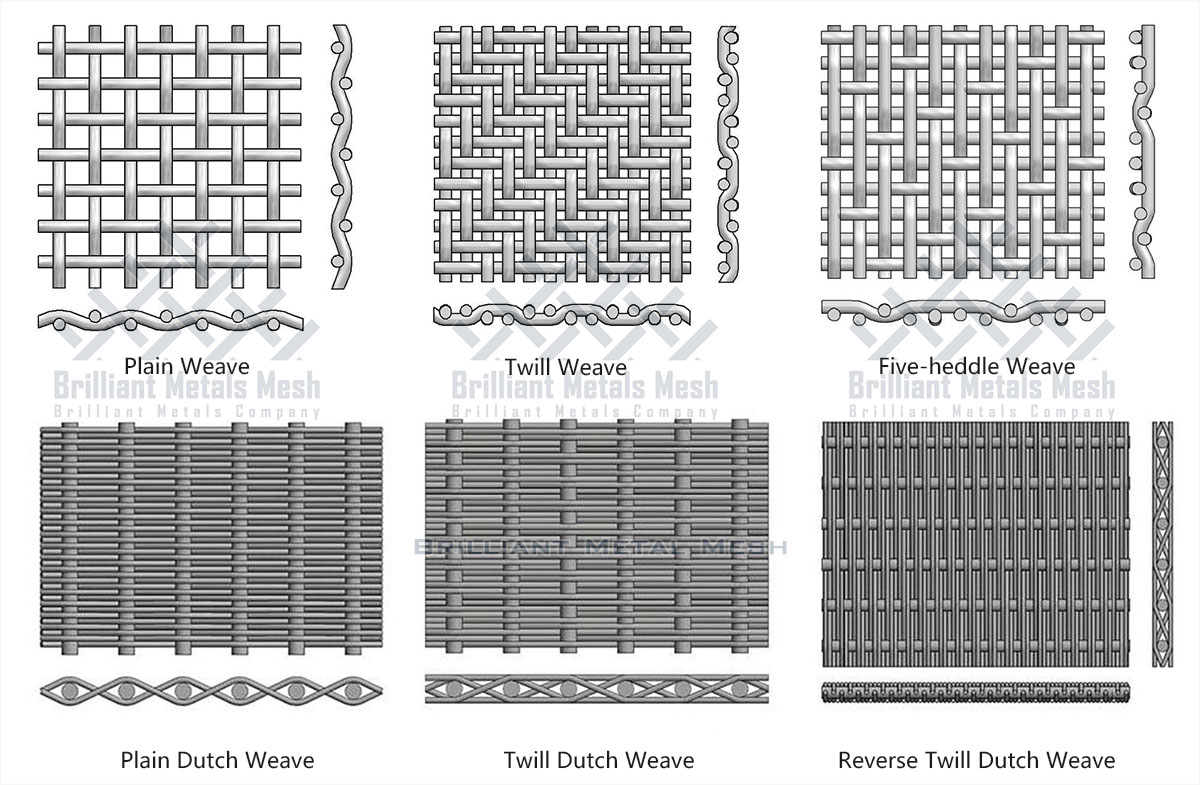

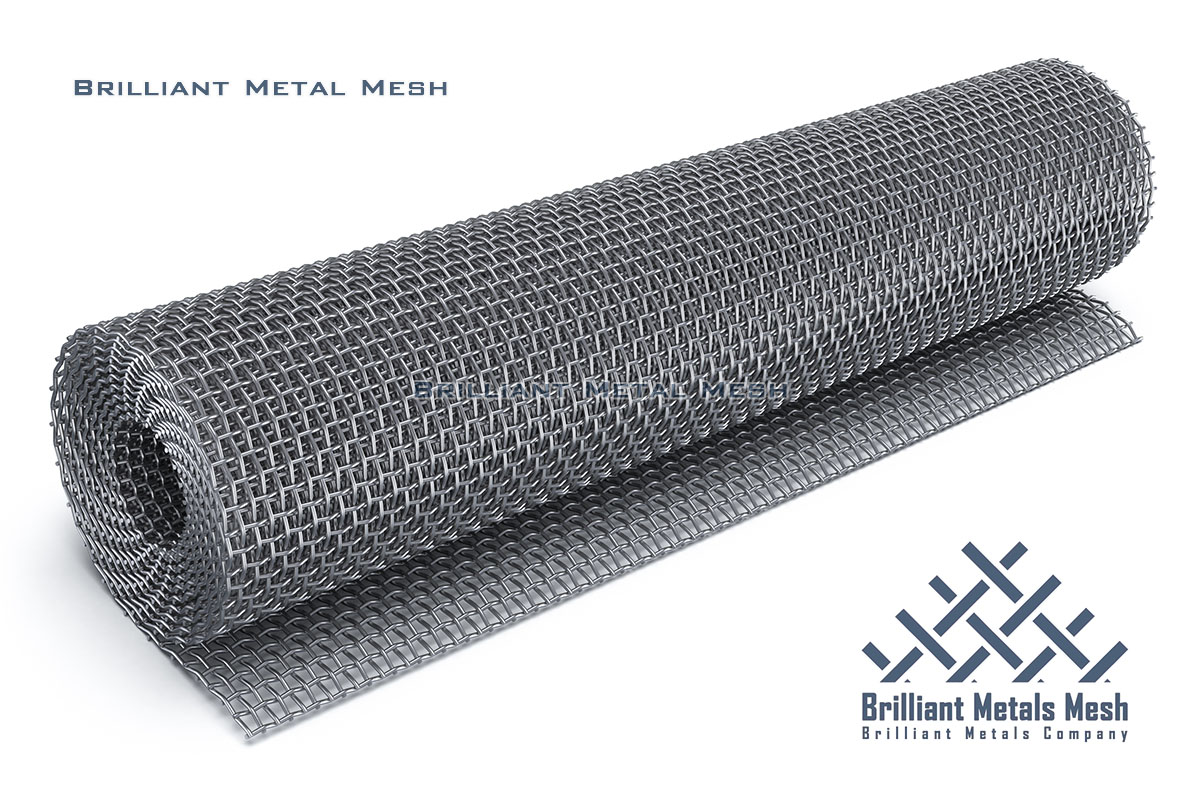

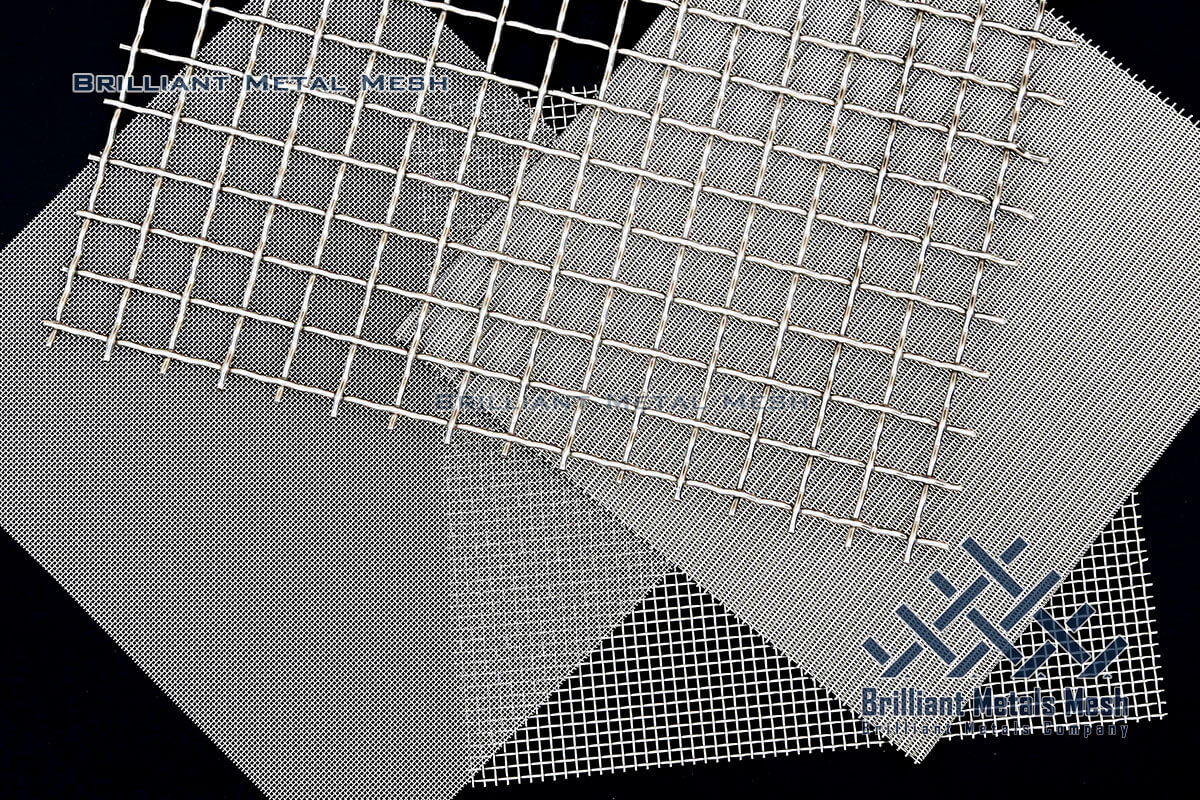

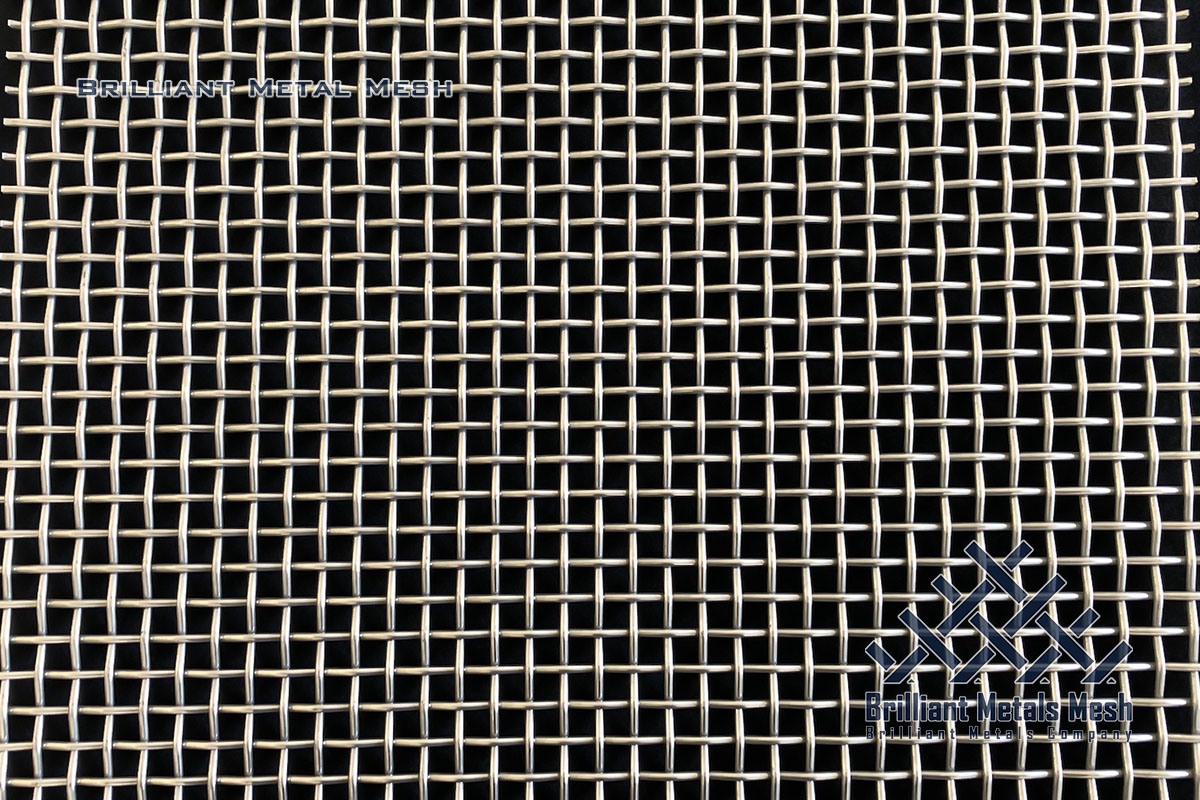

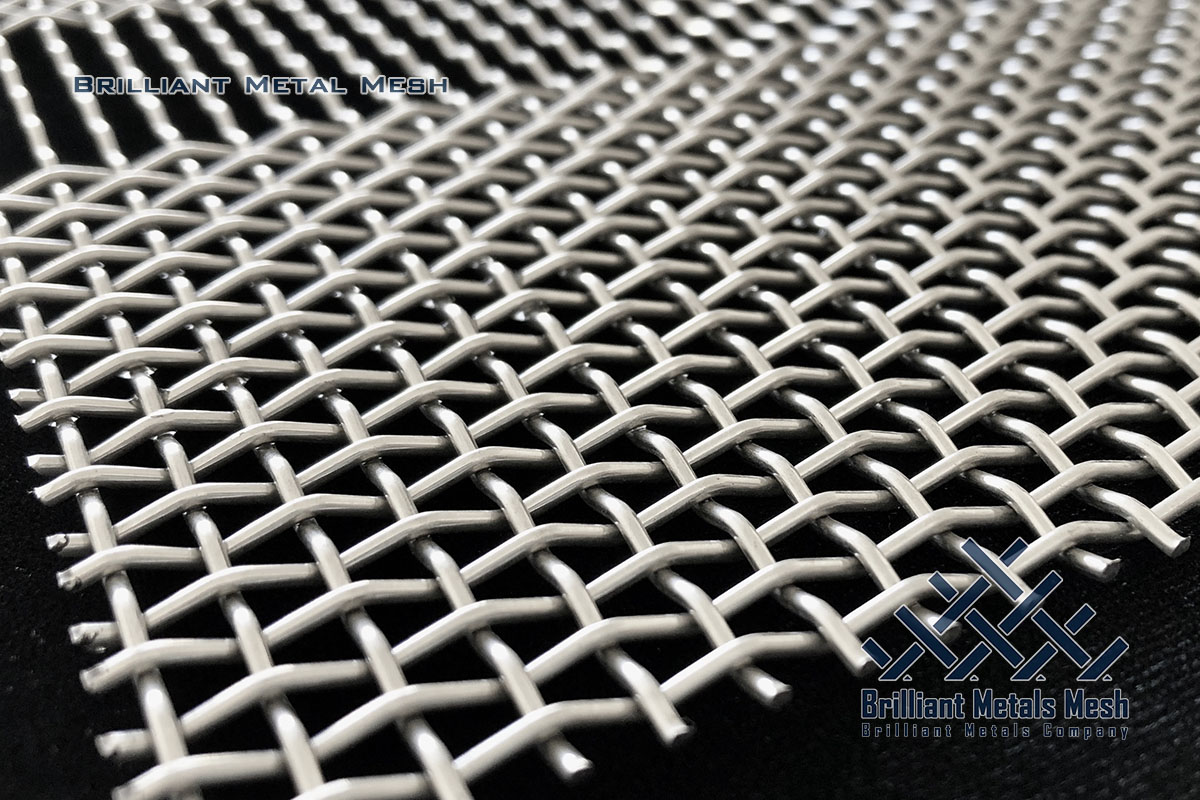

Stainless steel wire mesh is a type of woven material made from stainless steel wires. These wires are interwoven to form a mesh structure with uniform openings. The mesh can be woven in different patterns, such as plain weave, twill weave, or Dutch weave, depending on the application requirements. Stainless steel wire mesh is known for its durability, corrosion resistance, and versatility, making it suitable for various industrial, commercial, and residential applications. It is commonly used in filtration, sieving, security screens, architectural panels, and industrial processes where strength, cleanliness, and resistance to corrosion are essential.

- Wire Mesh Materials: 304, 304L, 316, 316L, 321, 310/314, 904L, Duplex 2205, 201, etc.

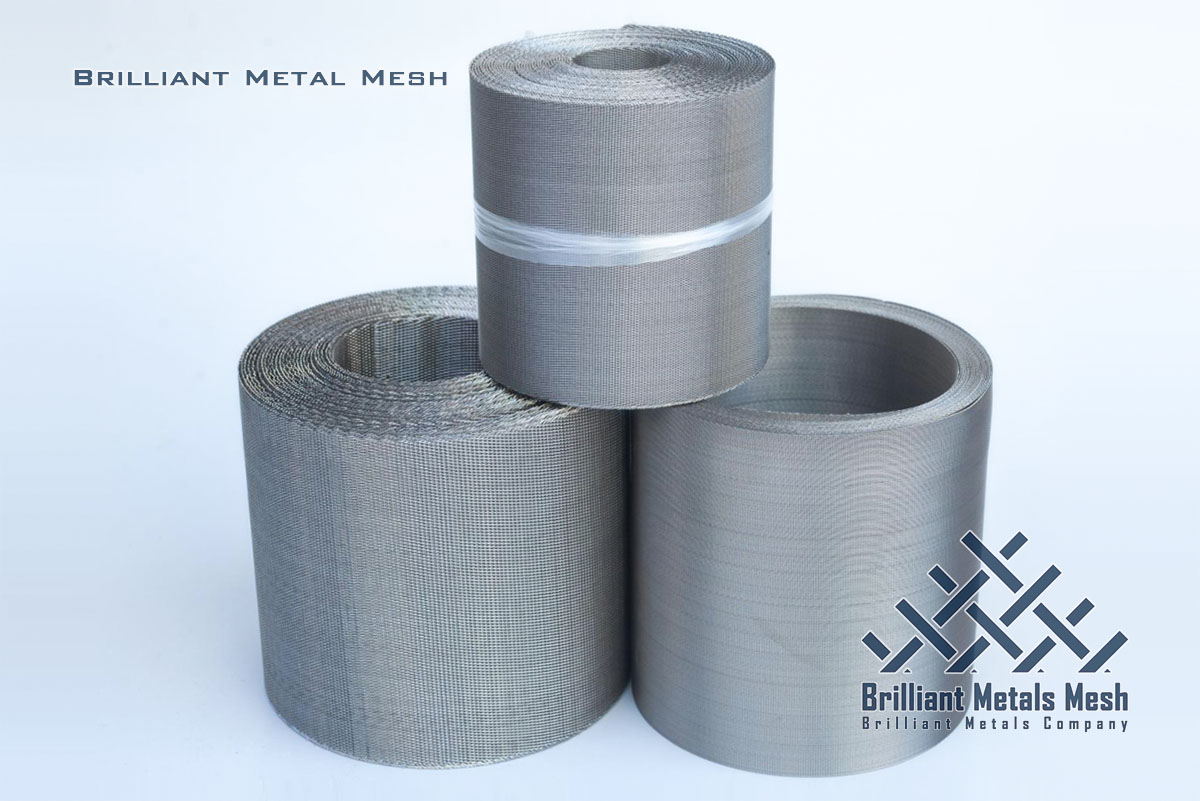

- Mesh per inch: 1 – 2800 mesh;

- Wire diameter: ≥0.02mm

- Width: up to 6m

- Typical Weaving Patterns: Plain Weave, Twill Weave, Plain Dutch weave, Twill Dutch Weave, Reverse Dutch Weave, Five-Heddle Weave, etc.